Quality inspection

The optical quality inspection service is mainly to make the physical product become a data format that can be recognized by the computer by three-dimensional scanning, then accurately overlap it with the original 3D design drawing and then inspect the size error of each part, which is a full-scale comparison method, also known as global inspection.

XTOP 3D provides professional quality inspection services, using self-developed measuring equipment to provide you with professional, accurate and comprehensive analysis reports.

Product quality control in production line

Shape and size inspection

Machining complex parts inspection

Processing quality inspection of castings, stamping parts, molds, injection molded parts, wood products and other products

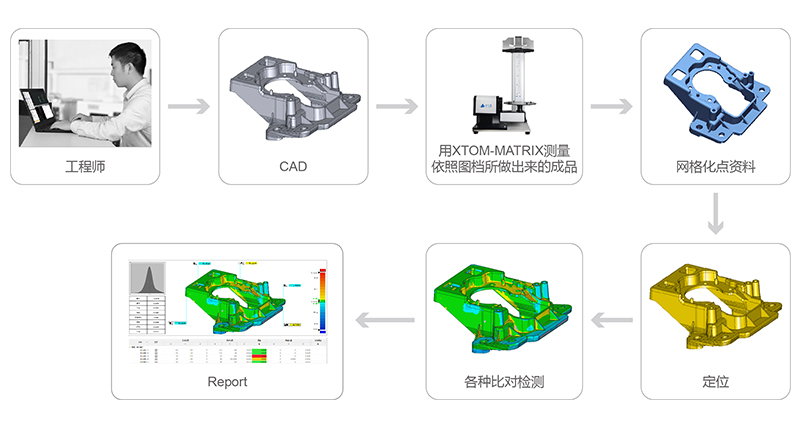

Quality inspection service process: